Just How Industrial Scales Can Streamline Your Service Procedures

Just How Industrial Scales Can Streamline Your Service Procedures

Blog Article

Why Industrial Scales Are Crucial for Enhancing Stockroom Workflow

Industrial scales play a pivotal function in enhancing stockroom procedures by providing accurate weight measurements that are vital for reliable inventory management and structured delivery processes. Their capability to ensure precision not just mitigates concerns of overstocking and stockouts yet likewise adds substantially to waste reduction and price effectiveness. Furthermore, the data generated from these ranges enables notified decision-making, enhancing source appropriation and functional performance. The true impact of commercial scales extends beyond plain accuracy-- understanding their broader implications could change functional techniques in unanticipated methods.

Enhanced Precision in Considering

In numerous warehouse procedures, accomplishing improved accuracy in weighing is critical for the total efficiency and dependability of supply monitoring. Exact evaluating enables for precise monitoring of item quantities, which is vital for maintaining optimum stock degrees and lessening waste. Industrial ranges designed for stockroom environments give high degrees of precision, consequently decreasing the margin for error in supply analyses.

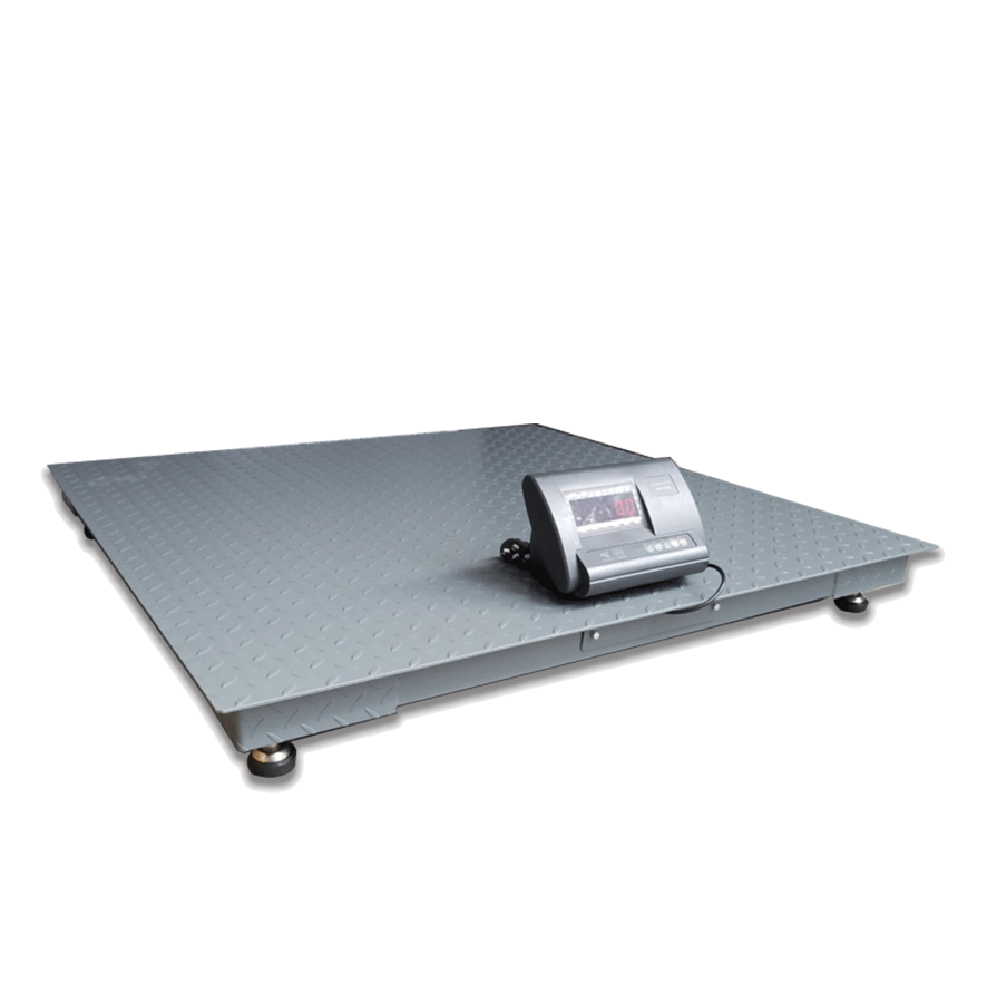

Applying innovative considering technology, such as digital scales with calibration functions, guarantees that weights are constantly accurate throughout different loads. This precision is specifically crucial when managing bulk products or high-value items, as inconsistencies can lead to considerable financial losses. Moreover, accurate considering adds to compliance with industry policies, which often mandate exact measurement for safety and security and quality assurance.

Moreover, improved evaluating precision enables much better decision-making regarding logistics and supply chain administration. With specific information available, storehouse managers can anticipate demand much more efficiently, strategy for replenishment, and optimize storage space utilization. Ultimately, the combination of precise commercial ranges into stockroom procedures sustains not just prompt operational demands yet likewise long-lasting critical goals intended at boosting overall productivity and earnings.

Improved Supply Management

Reliable inventory management is crucial for optimizing stockroom operations and making certain that sources are utilized effectively. Industrial ranges play an essential role in this process by providing accurate weight measurements that directly affect supply monitoring and control. By incorporating these scales right into stock monitoring systems, warehouses can attain real-time data accuracy, which is critical for keeping optimal stock degrees.

The capacity to consider products precisely permits for far better projecting and replenishment methods. With specific weight info, stockroom supervisors can determine inconsistencies between expected and actual supply levels, thus reducing overstocking or stockouts. This accuracy additionally aids in categorizing products according to weight, which can boost storage space efficiency and streamline order selecting procedures.

Additionally, boosted stock administration promotes better distributor partnerships and consumer fulfillment. Exact weight dimensions assist in conformity with shipping guidelines and minimize the probability of costly mistakes during the procurement process. In significance, commercial ranges not only improve the accuracy of supply documents however additionally add to general operational performance, ultimately resulting in decreased expenses and improved solution delivery in warehouse procedures.

Streamlined Shipping Procedures

A considerable element of stockroom efficiency is the streamlining of delivery processes, which can considerably boost overall efficiency and consumer fulfillment. Efficient delivery operations make certain that items are dispatched precisely and in a timely fashion, directly impacting consumer experience and retention.

Additionally, integrating industrial ranges right into warehouse management systems helps with real-time tracking of inventory and deliveries, boosting openness throughout the shipping process - Industrial Scales. This integration not only quickens the gratification cycle yet additionally boosts interaction amongst staff, leading to quicker decision-making and less traffic jams

Furthermore, streamlined shipping procedures can lower labor prices, as groups can function much more successfully with clear guidelines and exact information at their fingertips. By taking on industrial ranges, warehouses can accomplish a more methodical method to shipping, inevitably increasing their operational efficiency and supporting a more powerful profits.

Waste Reduction Techniques

Maximizing storehouse operations expands beyond structured delivery procedures to incorporate waste reduction techniques that significantly add to overall efficiency and cost-effectiveness (Industrial Scales). Executing commercial scales is a critical aspect of these strategies, allowing specific dimension of products and items, which lessens overages and decreases excess stock

An additional crucial strategy is the optimization of packaging. Industrial ranges promote exact weight measurements, enabling tailored packaging solutions that lessen excess materials. This not only lowers waste but additionally lowers delivery costs, as lighter plans typically sustain reduced products costs.

Data-Driven Decision Making

Making use of data generated from industrial ranges allows storehouse supervisors to track supply degrees much more accurately, resulting in notified purchasing decisions and decreasing overstock or stockouts. This data can be assessed to recognize patterns in product motion, enabling much better forecasting and source allotment.

The insights obtained from weight information additionally facilitate performance dimension versus key performance indications (KPIs), such as throughput prices and order precision. By utilizing advanced analytics, warehouse operations can reveal inefficiencies, enhance workflows, and minimize operational expenses.

Eventually, data-driven choice making equips companies to make aggressive modifications, guaranteeing that stockroom procedures stay dexterous and receptive to market demands. Buying industrial scales not only enhances data collection yet additionally transforms that data right into workable intelligence, placing warehouses for continual competition and growth.

Final Thought

In summary, commercial scales play an essential role in maximizing warehouse procedures through improved precision in weighing, improved inventory monitoring, and structured delivery processes. The integration of commercial scales into warehouse monitoring systems is therefore paramount for achieving optimum performance and resource appropriation.

Industrial ranges play a crucial role in maximizing storehouse procedures by supplying precise weight measurements that are essential for efficient supply administration and streamlined shipping procedures. Industrial ranges designed for warehouse atmospheres provide high degrees of precision, thereby decreasing the margin for error in stock my latest blog post assessments.

In essence, industrial scales not only boost the accuracy of inventory records however also contribute to general functional effectiveness, inevitably leading to decreased expenses and improved solution delivery in storehouse procedures.

In summary, industrial scales play a critical function in maximizing storehouse procedures through improved precision in weighing, improved supply monitoring, and streamlined shipping processes. The combination of industrial ranges into storehouse management systems is hence paramount for attaining ideal efficiency and source allotment.

Report this page